Raycreate: Pioneering Filipino Ingenuity in Advanced Additive Manufacturing Solutions

The future of additive manufacturing is at your fingertips with Raycreate’s innovative SLS 3D printing solutions.

Discover how we enable the transformation of SME industries and how your projects can thrive in this revolution.

Instant RFQ & QC: End-to-End Transparency

Streamlined STL Submission and Rapid QC Assessments: Submit your RFQs with a simple click HERE, and experience the efficiency of our RFQ module with its ability to produce instant transparency of cost, lead time, and geometry checks.

Complex Geometry Prints on Demand: Sustainable Design Freedom Unleashed

▷ Mechanical Accuracy with Complex Geometries: SLS technology excels in printing complex geometries that surpass the capabilities of FDM, DLP, and SLA technologies because of its mechanical reliability for seamless operation, especially for components requiring precise interlocking structures, from basic ball-socket joints to intricate chain-mail designs.

▷ Precision Detail Definition without Support Structures: SLS printing defines precision in detail without the need for support structures, this process guarantees the fidelity of the final product to its design specifications, enhancing the visual and functional quality of prints. This process guarantees the fidelity of the final product to its design specifications, enhancing the visual and functional quality of prints.

▷ Efficient Production of Hollow Structures: We leverage SLS technology for its ability to produce hollow structures without infill, resulting in minimized lead times and it maintains mechanical accuracy and precision of detail. This is pivotal sustainability for projects demanding quick turnarounds without compromising on quality or design complexity.

A function better than the sum of parts

▷ As a multi-faceted methodology, SLS can help you overcome problematic prototyping scenarios: External shareholder pressure, tight sprint schedules, and budget shortcomings can cause the lack of a proper development roadmap. SLS solutions make project step remaps feasible. For example; a systemic remap of 6 steps. 3 steps to validate individual part iterations, a 4th to combine the successes, a 5th to achieve full spec compliance, and a 6th to demo repeatability.

▷ The volumetric print capability of SLS also enables you to test hypotheses. With this validation approach, you can test any prototype vertical slice, shifting the emphasis from just printed output into an action-to-results-based methodology; This way you can yield profound results of exponential improvements to your development sprints and time-to-market performance.

Expertise in SLS 3D Printing: Your Trusted Partner

▷ Years of Experience: Benefit from our extensive experience in SLS 3D printing for the European and American markets.

▷ Customized Service Options: For all custom requests, including potential discounts, priority express service, and special shipping options.

▷ Streamlined Support: The Fabrex RFQ/QC module, with its monitoring and annotation system, ensures dedicated guidance and support for every project.

Bounding Box

Max 150 x 390 x 150 mm

Min 7.5 x 7.5 x 7.5 mm

The bounding box is a 3D imaginary outline of a box that encloses the smallest area occupied by your model. Your model must fit within the minimum and maximum bounding box sizes. If the size of the model is close to the maximum bounding box, then the printing orientation will be restricted.

Walls

Supported wall thickness Min 0.5 mm

Unsupported wall thickness Min 0.5 mm

A supported wall is connected at least on two sides of the wall, while an unsupported wall is connected only one side of the wall. Walls that do not meet the minimum requirements may not survive printing and cleaning processes.

Wires

Supported wall thickness Min 0.5 mm

Unsupported wall thickness Min 0.5 mm

A wire is a rectangular, circular or even triangular feature that is thinner in its

unconnected directions than its length. A supported wire is connected at least on two sides of the model, while an unsupported wire is connected on one side of the model.

Wires that do not meet the minimum requirements may not survive printing and cleaning processes.

Details

Embossed Details

0.2 mm high & wide for details

0.3 mm high & 0.5 mm wide for details

0.5 mm high & wide for text

Engraved Details

0.2 mm deep & wide for details

0.3 mm deep & 0.4 mm wide for details

0.5 mm deep & wide for text

A wire is a rectangular, circular or even triangular feature that is thinner in its

unconnected directions than its length. A supported wire is connected at least on two sides of the model, while an unsupported wire is connected on one side of the model.

Wires that do not meet the minimum requirements may not survive printing and cleaning processes.

Escape Holes

Single Escape Hole Diameter

4.0 mm & 10.0 mm

Multiple Escape Hole Diameter

2.0 mm & 8.0 mm

Escape holes are necessary to empty the support material of a hollow model.

Two escape holes at the opposite ends of the model is optimal for the support removal process.

Please consider the size of your model and make the escape holes bigger or add more escape holes as needed as minimum guidelines will not always be adequate for large models.

A single escape hole at the end of a cavity will not allow material in the corners near the escape hole to fully escape. So we recommend multiple escape holes at both ends of the cavity.

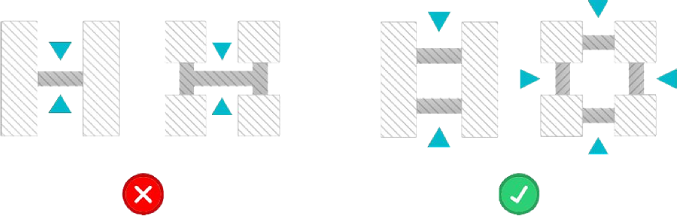

Clearance

Single Escape Hole Diameter

1.0 mm

Clearance is the space between two individual parts in a model.

If the space among the individual parts do not meet the minimum clearance, then parts can fuse together or can be difficult to clean.

This is important for movable pieces like hinges, gears, etc.

Sprues

2.0 mm thick, attached in at least 2 places per part.

Sprues are wires that keep two or more parts together.

Parts should be connected with a minimum of two sprues each.

Freedom from fear.

With our SLS service we can provide you with pathways away from this realm of fear and into a realm of enlightenment and resolve.